Track guidance

Track guidance on railways is provided by steel guideways (rails) and correspondingly shaped wheels, which are also made of steel. This is why we also speak of the wheel/rail system.

On all railways, track guiding devices limit the lateral play of the vehicles on the track to very low values. According to the EBO, the lateral play of the wheelsets in the track may be between 4 mm and 60 mm.

On the railway, the track guidance with its low lateral play is the essential prerequisite for being able to form trains which – depending on other prerequisites – can be several kilometres long and weigh up to approx. 20,000 tonnes. Although several locomotives are used for very long trains, which also run in the train or at the rear of the train to limit the draw hook load, these can be controlled by one driver from the front. This personnel saving is a major system advantage of the railway.

For railways as well as for tramways, urban railways and underground railways, the track guidance principle using flanged wheels with a conical running surface profile has proven its worth. Such a design leads to the following mechanism of action:

- The conicity of the wheels and the inclination of the running surface of the rails in wheel/rail contact is essential for the self-centring behaviour of the running gear in the gauge channel of straight tracks.

- The wheel flanges, on the other hand, are primarily required for driving through track curves with small radii. In this case, they form a positive stop with the rail, which strongly limits the transverse movements of the trolley to the specified line direction of the track. This stop is functionally intended. Although this results in increased stress, it does not lead to a loss of track guidance during further travel.

Wheel flanges

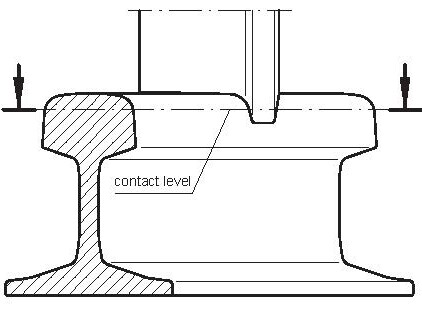

The wheel flanges are located on the inside of the wheels, i. e. towards the longitudinal centre line of the vehicle. Contact of the wheel flange flanks with the rail therefore always takes place on the inner side of the rails facing the track centre, which thus forms the running flank.

When guiding through curves, the wheel flange runs against the rail running flank mainly on the outer rails in the curve.

The inner wheel flanges lead to the fact that in the event of the wheel flange hitting the rail running flank, the associated wheel (unlike with outer wheel flanges) receives additional force components.

These additional wheel contact forces acting on the leading wheel when passing through a track curve arise from moments of the axle bearing lateral forces around the longitudinal axis of the running gear as well as from moments of the centrifugal forces acting above the flank contact of the wheel flange and the rail. As these moments act outwards in the curve, a corresponding reaction moment of the wheel contact forces arises. In this case, the wheels driving and guiding on the outside of the curve are also subjected to the contact force. This has the advantage of increasing safety against derailment. The wheels running on the inside of the curve are relieved.

If there are guiding devices next to the inner rail in the curve, these can transfer the guiding forces by the wheels running against them with their flange back flank or their wheel back. This has the disadvantage that the wheels travelling on the inner rail of the curve are subjected to lower vertical wheel contact forces than the wheels travelling on the outside of the curve, while the lateral guiding forces remain the same. As long as the lower wheel contact force compared to the wheel running on the outer rail of the arch is only a few percent, this is insignificant if there is sufficient safety against derailment.

Influence of track guidance on the guideway

The track forces acting on the track result from the interaction between the vehicle and the track. The magnitude of the forces occurring as a result of track guidance is significantly influenced by the alignment of the track. In particular, system-related reaction forces of considerable magnitude occur the faster a change of direction takes place and the smaller the curve radii are.

Safe track guidance

Safe track guidance requires that a wheel axle is guided as uninterruptedly as possible on both sides. In continuous track, this is ensured by the inner running flanks of the two rails approached by the wheel flange end flanks.

In switches and crossings, however, there are interruptions of the running flanks in the area of the crossings, which are not always safely covered by the chord length at the flange face at the level of the contact line of the flange and the rail running flank. In these cases, there are so-called trackless sections. In switches, uninterrupted track guidance is ensured by additional check rails.

In summary, the following applies to the switch area: The safe guidance of the wheel flange is always given if the guide dimension of the wheels belonging to a wheel axle is greater than the guide width in the direction of the transverse movement. If, in the direction of the transverse movements of a wheel axle, the guide dimension of the associated wheels is smaller than the guide width, the track guidance between the wheel guide and the wheel flange back or the wheel back is given.

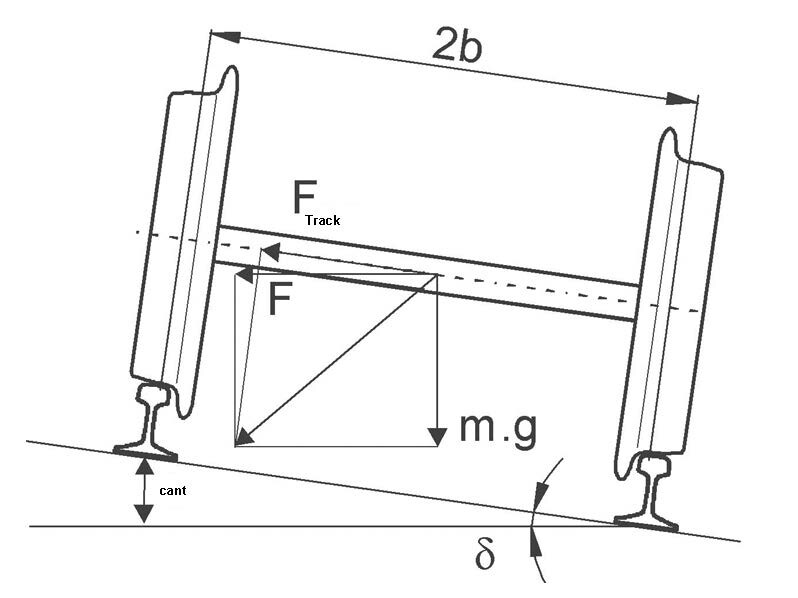

Wheelset in track cant

In order to reduce the lateral acceleration acting on the passenger, the track is usually canted I n the track curve. Track cant means that the outer rail is a certain amount higher than the inner rail. The track is therefore inclined by the angle δ.

Recommended specialist literature

Hansmann, Fabian; Nemetz, Wolfgang; Spoors, Richard, Keeping Track of Track Geometry

https://www.pmcmedia.com/en/all-titles/rail/428/keeping-track-of-track-geometry

Jänsch, Eberhard; Lang, Hans Peter; Nießen, Nils (Hrsg.), Handbuch Das System Bahn

https://www.pmcmedia.com/neuerscheinungen/427/handbuch-das-system-bahn?c=10

Wittenberg/von Lüpke/Zwanziger/Heinrichs (Hrsg.), Kommentar zur Eisenbahn-Bau- und Betriebsordnung (EBO)

https://www.pmcmedia.com/neuerscheinungen/422/kommentar-zur-eisenbahn-bau-und-betriebsordnung-ebo