Pre-Measuring for Tamping

Tamping machines can produce the track geometry very precisely according to the design. Traditional machines only take into account the relative track geometry such as horizontal curvature, vertical inclination and cant. The absolute track position and the correction values compared to the nominal track position cannot be determined. However, in order to position the track absolutely correctly, correction values can be transferred to the machines for lifting and lining (absolute method). The measurement related to the fixed points of these correction values is also named pre-measurement for tamping. Various measuring methods are available for this purpose:

· Manual pre-measurement with level and aligning instrument

· Geodetic pre-measurement with total station and track measuring trolley (e.g. Trimble GEDO Track)

· Pre-measurement with a twin-trolley system using the long chord measurement method (e.g. Trimble GEDO Vorsys)

· Pre-measurement with inertial measuring system (e.g. Trimble GEDO IMS)

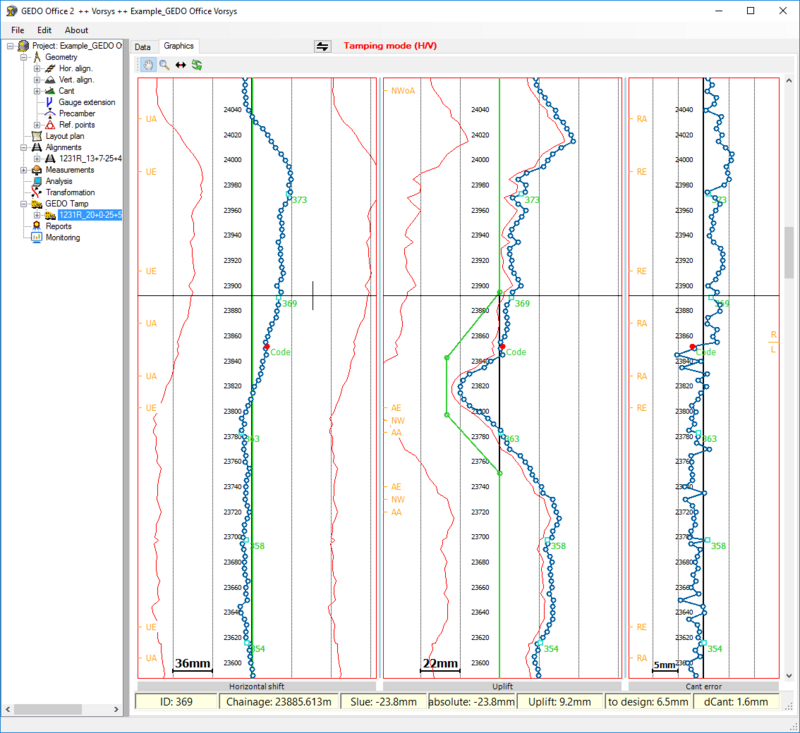

The result of these measuring methods is always the deviation of the current track position from the nominal geometry in a continuous grid. These values can be viewed in detail and prepared for the tamping machine. In this way, the final track position is defined, which is then to be produced by the machine. External parameters such as maximum shift, minimum and maximum lift as well as constraint points in the existing track are taken into account.

The final lifting and lining values are transferred in the data format corresponding to the tamping machine. A list view of the digitally transmitted correction values helps the machine guidance personnel to track which parameters were taken into account when defining the target track position.

Tamping work can begin without delay immediately after the digital data has been loaded. In addition to the lifting and lining values, the geometry information can also be transferred from the measuring system to the tamping machine. This digital data exchange prevents manual transmission errors and ensures that the same information is used as a reference for both the measurement and the machine work.

In friendly cooperation with ©Trimble Railway GmbH