Railway work and maintenance of way

The construction of railway lines requires high investments. However, with long lifecycles (for example, 30 to 50 years for the superstructure), the system can gain an economic advantage over other modes of transport. To achieve this durability, however, it is necessary to build and maintain the railway system at the highest quality level. In the early days, track construction was still associated with high staff costs, but today it is one of the sectors with the highest level of automation in the construction industry. From maintenance to the replacement of the superstructure, a large number of activities today are carried out partly automated and on a track-bound basis.

In friendly cooperation with Plasser&Theurer.

Construction and maintenance work ensure the high availability and serviceability of the track. They are economical if they combine a high initial quality with a large wear stock, low wear and minimal costs.

High quality or preventative measures when setting up the system can minimize or avoid problems. If they occur despite all care, they can be identified and eliminated in a short time by continuous maintenance by inspection, maintenance and repair. In the following, individual key procedures are briefly described:

Care of the contact geometry wheel / rail (rail running surface)

An optimal contact geometry wheel / rail and low dynamic additional loads in the vehicle / track system require continuous rail care (also preventive grinding) as well as immediate correction of rail defects. This is especially true for switches and crossings with their critical wheel arch and for dynamic additional loads in the tongue and crossing area.

Ballast bed

The advantage of the ballast bedding is its load distributing effect and the resulting protection of the substructure. The railway ballast transfers and distributes the loads from the sleepers over the substructure into the ground and secures the required position security of the track grate in horizontal and vertical direction. The railway ballast as a bedding must meet the high demands on the grain composition and the quality of the rock.

The track position is essentially dependent on the quality of the ballast used and the load applied. Due to the permanent dynamic loads from train traffic, in addition to elastic deflections, there are also permanent (plastic), uneven deformations in the ballast bed. In contrast to the desired deflection of the track grating, the plastic deformation causes a deterioration of the track position, which can only be remedied by maintenance work. The non-uniform setting of the track grate not only has a negative effect on the ride comfort, but also increases the impact on the system (load transfer).

Tamping machines allow a sustained correction of the track position and thus ensure the safe operation of the entire system. With increasing wear of the ballast and the progressive ballast contamination, this correction of the track position is no longer sustainable.

Bedding contamination and ballast wear can only be minimized by high-quality ballast cleaning (see Fig. 1). This will restore the original properties of the ballast as bedding. These include the sufficient shear strength and drainage capability of the ballast as well as a constant transverse slope.

- Excavation of the old ballast with a clearing chain.

- Screening of undersized and oversized grain.

- Cleaning by sieving, bouncing, washing.

- Installation of the cleaned ballast.

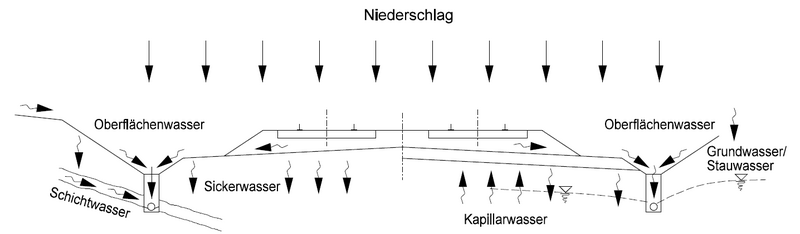

Drainage

Dewatering measures can reliably prevent water retention with water accumulation in the soil and thus a critical increase in the water content with a change in consistency and increased deformability. On the railway, the cross-section, the open railway ditches, the interception ditches and the associated predrainage systems take over the setting and discharge of surface water. Deep drainage systems are arranged as an underground drainage system for receiving and discharging unbound soil water.

Wear and protective layers

Protective layers are a layer system applied to the subgrade, which protects the pending soil from damaging deformations and frost effects. They are produced from grain mixtures and their effectiveness can be improved or supplemented with geosynthetics, transitional layers or soil improvements as additional measures. The installation of a protective layer can be trackless or track-bound (see Figure 3). Functional drainage systems are part of the initial quality of a high-quality track and load-bearing or protective layers on fine-grained soils.

- Excavation of mixing zone and soil.

- Making the subgrade in height, inclination and width.

- Installation and compaction of the base course.

- Combination of the base layer with geosynthetics possible.

Elastic elements for modification of the structural behavior

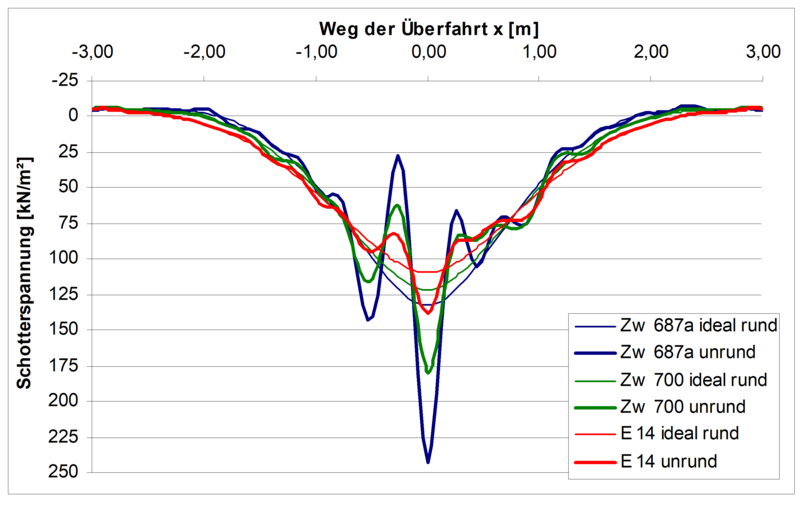

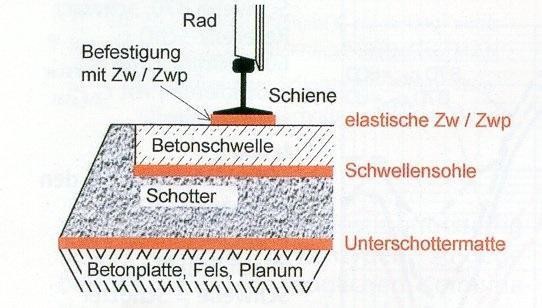

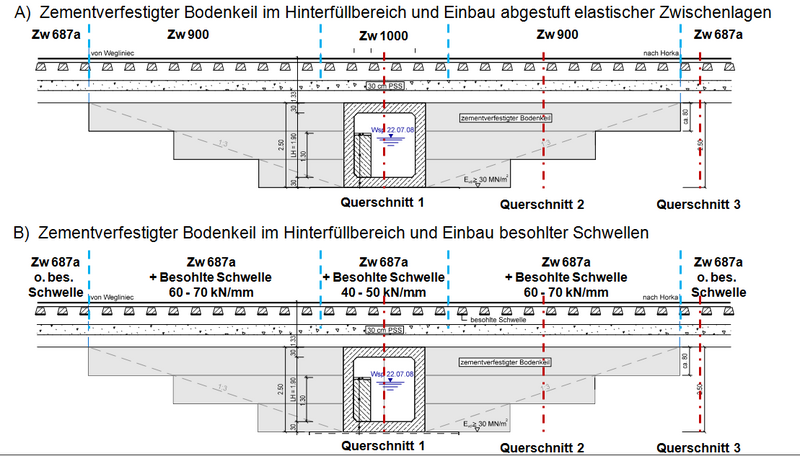

To increase the initial quality and to reduce wear / deterioration, higher elastic elements are used in the superstructure. With the arrangement of additional elastic elements in the superstructure noise and discontinuity points can be eliminated. The stress is reduced both statically and dynamically and the stiffness in the track support is made uniform. The spring element causes a higher rail depression and a larger bending line and thus, with high quality of the support system, a significant reduction of the power at the reference point and the ballast voltages.

To reduce the effects, the elastic elements can be arranged in different positions under the rail (as intermediate layer), under the tie / sleeper (as sleeper / tie sole) or under the bedding (as under ballast mat).

With higher-elastic elements, the stiffness in the longitudinal direction of the track can be effectively equalized out (eg in transition areas).

The deformation behavior of the support system has been expressed by the bedding modulus C as the ratio between the sleeper / tie pressure and the elastic pressure of the sleeper / tie (load transfer). With the use of elastic elements, the rail support determines the deformation behavior of the system so that the track stiffness kG can be introduced as a module.

By choosing the positions and stiffness of the higher-elastic elements, the support can be effectively optimized. The reduction of the dynamic load and the equalization of the stiffness in the longitudinal direction of the track gain importance with increasingly higher speeds.

In friendly cooperation with GEPRO Ingenieurgesellschaft.

You can find suitable specialist literature about the topic here:

Best Practice in Track Maintenance, Vol 1 - Infrastructure Management

Infrastructure Management Volume 1 looks at aspects of infrastructure management with particular reference to the single European railway area. Based on best-practice examples from Central Europe, measures for the targeted retrofitting and improvement of the infrastructure maintenance of the existing network are presented. In many cases, infrastructure operators are faced with a generational change, which accelerates the process. Modern information and communication technology can simplify the comprehension and presentation of complex contexts. Modified approaches to asset management and life-cycle management enable implementation of the "transparent permanent way" or the "railway 4.0".

The Basic Principles of Mechanised Track Maintenance

This book is dedicated to the many people involved in the day to day planning and performance of track maintenance activities. Providing a practical approach to everyday challenges in mechanised track maintenance, it is not just intended as a theoretical approach to the track system.

Railways aim at transporting people and freight safely, rapidly, regularly, comfortably and on time from one place to another. This book is directed to track infrastructure departments contributing to the above objective by ensuring the track infrastructure’s reliability, availability, maintainability and safety – denoted by the acronym RAMS. Regular, effective and affordable track maintenance enable RAMS to be achieved.